New Products

Find Beer Brewery Equipment, Brewery Equipment, Small Beer Brewery Equipment on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

| Min. Order: | 1 Set/Sets |

|---|

beer brewery equipment,beer fermentation equipment,beer brewing for sale

15hl Beer Brewery Manufacturing Equipment

1) Automatic /semi-automatic operation system ,need one or two brewer operate

2)With our equipment you can make different kinds beer such as ale,lager, IPA, stout beer and so on, we supply the brewing recipes

3)We have different capacity from 50L to 10000L per batch , our brewery equipment approved Pessure CE, ISO ,ROHS,TUV certificate

4) Have good feedback from our clients

5) Installation/Operation/ Service/ Maintenance Manual: Provided In English.

beer brewing equipment Technical Parameter

| Items | Honglin-100L | Honglin-200L | Honglin-300L | Honglin-500L | Honglin-1000L | Honglin-2000L |

| Production capacity | 100L/day | 200L/day | 300L/day | 500L/day | 1000L/day | 2000L/day |

| Floor space | 15m2 | 25m2 | 35m2 | 50m2 | 80m2 | 120m2 |

| Total power

| 12kw | 12kw | 12kw | 15/36kw | 22/72kw | 31/144kw |

| Water | 0.5m3/d | 1.0m3/d | 1.5m3/d | 2.5m3/d | 5m3/d | 10m3/d |

| Consumption of malt | 20kg | 40kg | 60kg | 100kg | 200kg | 400kg |

| Consumption of hop | 60g | 120g | 180g | 300g | 600g | 1.2kg |

| Yeast | 100g/1L | 200g/2L | 300g/3L | 500g/5L | 1kg/10L | 2kg/20L |

| Max steam |

| 0.017t/hour | 0.017t/hour | 0.05t/hour | 0.10t/hour | 0.20t/hour |

| Remark: The above material consumption just for reference, actual consumption depends on customer's processing technology. | ||||||

Equipment Application

Today, beer is becoming more popular in the world, and beer have become an important part of people's daliy life, and even become a culture. Those micro beer brewing equipment made by our company are made of SUS 304/316L. You can installed it in bar, pub, restaurant, brewery, and tourist shopping center, and so on.

Malt milling system

Malt miller

Function: Grain crushing.

Component: It is made of miller, motor, belt, belt pulley, roller, hopper and so on. It is the first part ofstainless steel 304 brewing equipment.

Types: Stainless steel or Carbon steel.

Advantage: new design, the distance between 2 roller can be adjusted. This machine can remove the iron and dust by automatically.

Function: Crushing malt, and put it to mash tun for mashing.

Mashing system

Function: Grain mashing, wort filtration, boiling, and whirlpooling.

Component: It is composed of mash tun, lauter tank, kettle, whirlpool, hot water tank, hops back, plate Heat Exchanger with oxygenation device, wort pump and etc. It is the second part of micro beer brewing equipment.

Types: 2 Vessels brewhouse, 3 Vessels brewhouse, 4 Vessels brewhouse

Heating method: Electric heating, Steam heating, Direct fire heating.

Control method: PLC Screen controller cabinet or PID Instrument Panel.

Material: Food and sanitary grade stainless steel 304/316, Luxury red copper.

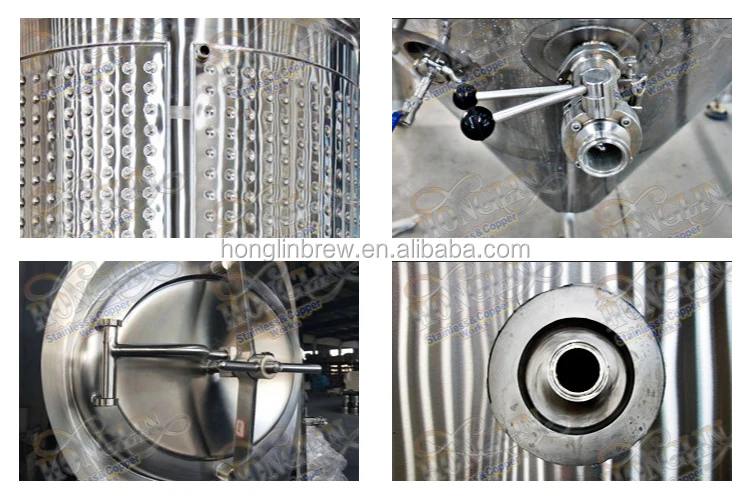

Fermentation system

Fermentation tank

Function: Wort fermentation or maturtion.

Component: It is composed of Shadowless manhole, Pressure relief valve, Aseptic valve, Pressure gage, Rotate racking arm, Butterfly valve, Pressure relief valve and so on. It is the third part of micro beer brewing equipment.

Types: 50L-10000L, and even bigger volume.

Cooling method: Ice water belt or glycol cooling jacket around both top and bottom.

Design pressure is 0.3MPa; Working pressure is 0.15MPa.

Material: Stainless steel 304/316/316L.

Glycol cooling system

Glycol water tank

Function: Glycol water supply for wort cooling and fermentation cooling.

Component: Glycol water tank, Solenoid valve, Pump, PPR and etc. It is the fourth part of thestainless steel 304 beer brewing equipment.

Cooling method: Single stage cooling (cold water cooling) and Two stage cooling (Glycol water and tap water cooling).

Control method: Automatically by PID/PLC Controller cabinet.

Tips: ( single stage cooling)

Some experienced brewers prefer cold liquor tank(cold water tank) for cooling the wort in the heat exchanger. The wort can be cooled much quicked than before. Accordingly, the cold water would also be heated to a high temperature. In this case, the cold water passing the heat exchanger would be recycled to hot water tank directly. This kind flow can save much energy.

The most important advantage is the wort would not be polluted when the heat exchange is broken.

COOLSOON Chiller

Function: Glycol water chilling

Chiller brand: World famous Australia COOLSOON.

Component: Compressor, Water pump, Evaporator, Pressure controller, Condenser, LCD temperature controller, Expansion valve, Dry filter, Hand valve, Draught fan and so on. It is the fifth part of the beer brewing equipment.

Advantages: Work highly efficient, Cooling faster and stable, If there have something wrong in the future, it is very easy to find spare part in anywhere.

Controlling system

Controller Cabinet

Function: Brewery controlling

Component: Instruments, Button, Speed controller, Intermediate relay, Switches. It is the sixth part of the beer brewing equipment.

Electric parts: World famous brand with CE certificate

The brand of temperature controller is AndongNi, Intermediate relay is Schneider.

Purpose: Show and control all the tank’s temperature, Control the show on/show off of motors, pumps, and solenoid valves.

Cleaning system

Cleaning car

Function: Caustic liquid heating and mixing

Component: Disinfection tank, Alkali tank, Pump and so on. It is the seventh part of the micro beer brewing equipment.

Purpose: It is used for cleaning all the tank when it finish the brewing.

Jinan Honglin Beer Equipment Co.,Ltd is a professional manufacture of brewery equipment,certified by CE,ISO,ROHS and TUV.We are specialized in brewery design,manufacture,installation and commissioning.With fine workmanship,excellent performance and simple operation,Honglin Brewery Equipment is your wise choice for beer brewing.No matter in appearance,quality,technology or service,Honglin product stands for the top level of beer brewing equipment domestically and worldwide.As an Original Design Manufacture,Honglin Brewery Equipment perfectly fits various brewing process.Our engineers had been sent all over the world for brewery designing,installation, training and technical supporting .

Advantages

1. About the raw material:

About the sanitary stainless steel 304 , we use 3mm interior shell and 2mm exterior shell.

2. About the drawing:

Generally our technician will design the suitable layout accordingly before production once our customers confirmed their orders.Then our workshop will do the manufacturing strictly according to the detailed drawing.

3. About the welding and polishing:

We make sure the 100% TIG welding with pure argon gas shield. We use the central system of argon, instead of ordinary gas cylinder.The argon will help to reduce the oxygenation. After welding, they will be polished to arrive to 0.2~0.4 μm without dead corner firstly, then do acid pickling and passivation.Which will help to remove the oxygenation on welding line; and form protection film on the steel to avoid rust. It will help you to extend the tanks life time.

Here are our advantages:

Here are our advantages:

1.We are one of the biggest pharmaceutical, beverage and brewery equipment manufacturers in China with more than 10 years experience.

2.Strong productivity of kinds vessels, we can produce satisfied product according your design.

3.Advanced technology assures strong welds and smooth seams.

4.Attention to detail at every step.

5.OEM / ODM services ,we provide one-stop services from one concept to a real product , and we can offer you very competitive prices

Benefits

1. Appearance clean and generous: The tank is polished by pickling and passivating, and the equipment is bright;

2. Good insulation effect: The equipment is divided into heat insulation and cold insulation, which is the best to ensure the temperature of the beer brewing process;

3. Intellect operation: the equipment is controlled by PLC, and the fermentation tank is equipped with a glass tube level gauge, which is convenient for visual operation;

4. Low energy consumption: environmental protection, energy saving, low power consumption, saving energy consumption of about 30%.

Evidence

| Pre-Sales Service | |

| FAQ | Frequently Asked Questions about starting a brewery |

| Consumption Calculations | To help the buyers figure out every cost |

| Design | Drawing with full dimensions and nozzle orientation Layout of the whole systerm based on client’s place |

| Video introduction | Showing and teaching how to operate the whole system |

| After-Sales Service | |

| Installation | Engineers available to service machinery overseas.The customer will be asked to provide room, board, round-trip transportation, and a nominal daily subsidy. |

| Technical support | Solving every question happened in operating the equipment. |

| Training | Providing full recipes and tutoring of beer brewing. |

| Upgrading support | Available to help clients to expand their breweries by sending replaceable spare parts, adding tanks, re-designing layout anytime. |

Shipping and delivery

1. All tanks will be packaged with soft protection material and mounted on strong carbon steel frame

2. All accessories and spare parts will be packaged with seperated box.

3. After loaded into containers, all equipments will be well fixed to the containers.

Product Categories : COMMERICAL BEER EQUIPMENT