New Products

Find Home Beer Making Machine, Beer Brewing, Home Brewery Equipment on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

| Min. Order: | 1 Set/Sets |

|---|

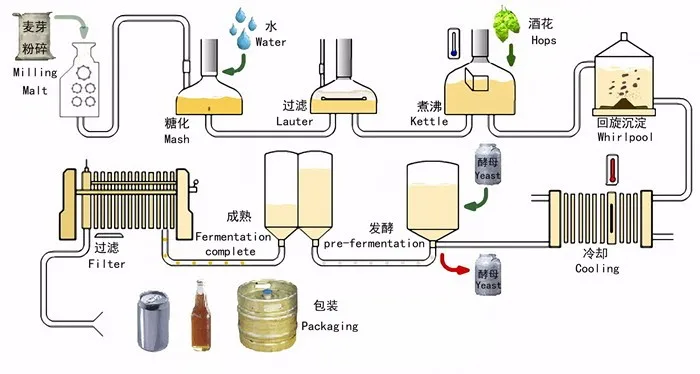

brewing process:

Milling:

mashing:

Mashing is the process of mixing milled malt and water, then heat this mixture. Mashing allows the enzymes in the malt to break down the starch in the grains into sugars. Mashing involves pauses at certain temperature(notably 45-62-73℃ or 113-144-163℉). Mashing takes place in mash kettle.

Lautering:

Lautering is the separation of grains and liquid. The bottom of lautering kettle has thin slits to hold back the solids and allow liquids to pass through. The mash itself functions as a sand filter to capture mash debris and proteins through recirculation. Grain washing also takes place in the lautering tank. After the wort runs-off, trickling water will goes through the grain to extract sugars.

Boiling:

After lautering, the wort will be boiled with hops ( and other flavouring if needed). Average boiling time ranges from 45 to 90 minutes, depending on its intensity, the hop addition schedule and water volume.

Whirlpool:

At the end of the boil, solid particles in the hopped wort are separated from whirlpool tank. Then wort will be cooled when runs into the fermentation tank through the plate Heat Exchanger.

Fermentation:

It takes place in fermentation tank. Sugar in wort will be transformed into ethyl alcohol by respiratory action of yeast. At same time, some other chemical and physical reaction happens too. Wort turns into beer gradually under these reactions.

After fermentation, we can drink beer directly or put beer into BBT via filtering equipment.

These processes are finished in several tanks. Tank quality can be customized.

Detailed Description

|

Item

| Model | Technical Specifications |

| Malt Miller | 80kg/h | two roller mill, carbon steel shell, alloy rollers complete with motor, belt and pulley, motor power 1.1kw |

| Mash Tun | 100L | effective capacity 200L, total capacity 300L,top dished head, dimensions 910x1870,material SUS304,cladding surface mirror finish, welding seams brushed,electric heating elements, rockwool insulation, thickness 80mm, |

| Lauter Tun | 100L | effective capacity 200L, total capacity 300L,top dished head, material SUS304,interior sand polished, cladding surface mirror finish, welding seams brushed |

| Fermentation Tank | 100L | effective capacity 200L,total capacity 260L,top dished head, bottom cone, dimensions660×2175, material SUS304, interior sand polished |

| Yeast Adding Tank | 2L | effective capacity 2L, inside polished outside sand blast, associated valves and fittings |

| Glycol Tank | 500L | effective capacity 500L, total capacity 560L, dimensions 960x1720, material SUS304,interior sand polished, |

| Glycol Chiller | ZD-B-ZL-4-2 8200w/h (4HP) | Refrigeration capacity 8200W (4HP), air cooling unit, CE approved, environment protecting Freon, designed for local power supply |

| Sanitizer Tank | 50L | effective capacity 50L, interior & exterior 2b finish, welding seams brushed,associated valves and fittings |

| Caustic Tank | 50L | effective capacity 50L, interior & exterior 2b finish, welding seams brushed, associated valves and fittings, electric heating elements |

| Control Cabinet | 600×350×1500 | power supply, temperature display centrally,Brewhouse manual control, fermentation tanks separate control with digital controller separately, variable frequency control for motors, pumps, etc. |

| Digital Controller | c2015 | separate control for each fermentation tank, temperature local display & control on controllers |

detailed images

Accessories:

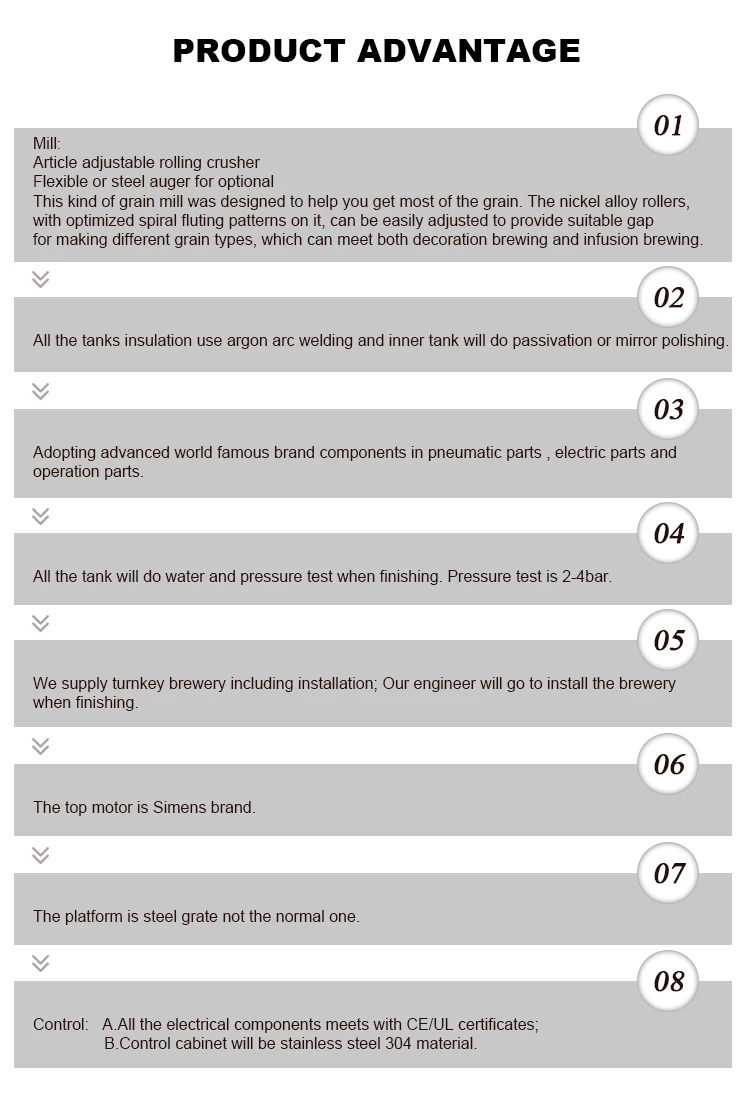

Home Brewing Equipment Advantages

1.Easy to operate : DCS semi-automatic control system,offer instruction manual.

We also provide personal training servie.

2.Easy to clean : Equipment with CIP System and spray cleaning ball.

3.Compact: only need 2-3 sq.m.

4.Movable: Equipment with wheels,easy to movable.

5.low price :stainless steel 304 material and all the pipeline valve is stainless steel.

6.beer:can brew ale,lagre,etc.We will teaching the brewing technology.

7.warranty:Main machine 3 years' warranty, all life service.

8.Technology:Fermenting

Why choose us:

1.Specialist manufacturer

We have own factory,we get CE certification. We specialize in manufacturing beer brewing equipment.

2.Quality and price

We have professional purchasing team. Comparing multiple vendors,then choose best raw materials and the most preferential price. We have skilled worker and strict quality control system,provide the best quality products to our customers.

3.Convenient transportation

Our company is located in Jinan,Shandong,which is near Qingdao port .It just take 2 hours from our factory to Qingdao port.

4.Clear order process

We have clear order process. From mails &calling→→order confirmed →→make advance payment→→workshop produce→→pay the balance→→deliver goods→→buyers receiving confirmation→→satisfaction survey.

5.Quality of service

We will provide photos to make our customers know the order status. Of course,we welcome our customers to our factory to inspect any time.

1.Pre-sale service:

1. The 24hours marketing team service.

If you are interested in any product, please don't hesitate to contact us. We will quote you, and give you all the details you need at first time.

2. We can provide company’s qualification certification and the drawings.

All of our products are passed CE, TUV, GMP , ISO, FDA test. We can show you our qualification and certification. And we can provide the drawings to make you use our products well as quickly as possible.

2.After-sale service:

1. We provide long-term after-sale service.

We don't just provide Mini Brewery Beer Manufacturing Plant For Brewing Mash Tun Brew Kettle, the service after sale is same important for us.

2. Owing to the quotation of our equipment is FOB price which excluded charges of door-to-door service. Thus, if necessary, we can appoint our technician to debug the machine with air ticket, visa, accommodation and labor cost provided by your party. Or you can send your technician to our company to learn techniques.

Product Categories : Homebrewery/pilot brewery equipment