New Products

Find Beer Brewing System, Beer Brewing Equipment, Micro Brewery Equipment on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

| Min. Order: | 1 Set/Sets |

|---|

Stainless steel 200L 300L 500L small BEER BREWING SYSTEM micro brewery beer brewing equipment

Micro home brewing equipment of standard configuration:

1. Two or three vessels 300L Brewhouse: mash/lauter tank, kettle/whirlpool tank or mash/lauter tank, kettle tank, whirlpool tank, wort grant, diverter panel,

2. Steam or electric heating,

3. Four or six 500L fermenters

4. 50L CIP

5. 4HP chiller and 1000L glycol tank

6. DCS semi-auto control system, seperate control for each fermenters

1. Brewhouse

2.Fermentation Tank

3.Glycol Tank & Chiller

About Us

1. We have a high efficiency after-sales service team. As a professional beer equipment supplier, we regard after-sale service as important as equipment quality, especially for international customers. 1. We dispatch our engineer to all the customers who need.

2. Customer can ask for engineer dispatching service not only at installing, trainning and debuging, also at the whole working life of the machine we delivery.

3. The engineer will come to the agreed place at the confirmation of After-sale Department, and no longer than 10days after all the documents include Visa and airticket finished.

4. Customer will bear the cost of above document and daily life of engineer in oversea.

5. All the spare parts will be offered at the price confirmed by After-sale Department.

6. Spare parts will be sent out in 24hours after payment finished. 7. The spare parts are free offered in the warranty period of machine.

Overseas installation showcase

Brewery list

| Equipents Request | Components |

| 1. Milling System | Malt Miller |

| 2. Mashing System

| Mash/Lauter Tun, Boiler Tank, Boiler, Heat Exchanger, Wort Pump, Other accessories are available: 1. Ornamental Pipe; 2. Mashing Pipeline; 3. Operating Plateform; 4. Yeast Feeder; 5. Venturi Tube; 6. Butterfly Valve DN40; 7. Butterfly Valve DN32; 8. Soft Pipe; 9. Dregs Rake; 10. Sugar Measuring Cylinder; 11. Saccharimeter; |

| 3. Fermenting System

| Fermentation Tank, Other accessories are available: 1. LPipe; 2. Butterfly Valve; 3. Pressure Gage; 4. Solenoid Valve; 5. Vacuum Valve; 6. Cooling Pipe; 7. Thermal Insulation Pipe; |

| 4. Cooling System

| Ice Water Tank, Refrigeration Machine, Centrifugal Pump, Evaporator, Ice Water Pump, Relative Pipes and Valves |

| 5. CIP System

| Washing Tank, Sterilization Tank, Pump and Valve |

| 6. Controlling System

| Mashing Control Panel, Fermenting Control Panel, Refrigerating Control Panel |

Once equipment is installed to form the brewing "system", you can begin to produce fresh, craft beers.

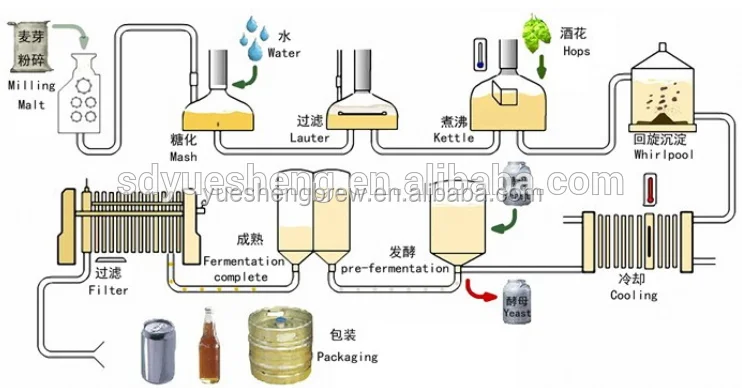

Here are the steps of the brewing process as the ingredients flow through the system:

[ 1 ] - MILL

A high-quality, adjustable, two-roll mill crushes the barley to the desired coarseness to form grist.

[ 2 ] - COMBI VESSEL

Actually two tanks in one: In the top unit, called the Mash/Lauter Vessel, grist and hot water are mixed to produce mash.From this, a clear substance called wort is extracted. The bottom unit of the Combi VEssel holds the additional hot water (liquor) needed for brewing and clean-up.

[ 3 ] - MANIFOLD

During the brewing process, wort and hot and cold water must move easily through the brewhaouse. The Manifold is a nine-valve control station which allows all liquid to transfer in a safe, sanitary manner. This eliminates liquid spillage and contamination, which may occur when connections or disconnectiong hoeses and clamps, or using swing arm panels.

[ 4 ] - BREW KETTLE

Here wort is brought to boil and mixed with hops, which adds bitterness and aroma to the mixture. Depending on customer preference, the Brew Kettle can be directly gas-fired or steam heated. It mau ca clad in stanless steel and copper, or furnished with the classic onion0shaped dome.

[ 5 ] - PLATE Heat Exchanger

Using tap water, chiled water, glycol or a combination of the three, this compact unit efficiently cools wort before it's transferred to the fermenter. The Exchanger also returns excess hot water to the Hot Water (liquor) Tank for use in the next brew.

[ 6 ] - FERMENTERS

Here yeast is added to wort to create the distinctive composition and flavor of beer. Our special disign allows for fermentation, aging, carbonation and lagering all in onetank, if desired. This saves the brewer time and minimizes space. Fermenters are individually temperature controlled. (ASME Code Approved Optional.)

[ 7 ] - FILTER

At this stage, yeast is removed from the mixture, eaving brillantly clear beer. A palte-and-frame or horizontal diatomaceous filter is employed to recover every last drop of beer to minimize and filter the product for packaging.

[ 8 ] - SERVING VESSELS

These units receive and hold the filteres beer for direct service to the bar. Or thay may be used as holding tanks for packaging the product. (ASME Code Approved Optional.)

Packaging: Iron crate, wood box,suitable for long distance sea transport packaging or wooden case.

Shipping: Shipped in 30 working days after payment.

Product Categories : Microbrewery system