New Products

Find 2-3 Bbl Electric Brewing System, Beer Making Machine, Turnkey Beer Brewing System on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

| Min. Order: | 1 Set/Sets |

|---|

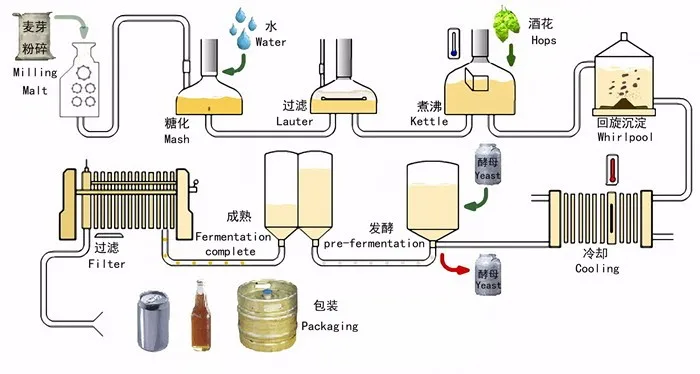

Microbrewery equipment product instructure:

The complete set of beer equipment Includes Malt mill device, Saccharification system,Fermenting system, CIP System, Refrigerator units,Electrical control cabinet and assorted pumps,valves etc.

We also can offer you filtering machine, filling line or bright beer tank if needed;

2-vessel: mash/lauter tank and kettle/whirlpool tank

Combination tank: lauter/whirlpool tank, kettle

3/4 vessels is also available if pub brewery space and operation needed

Hot water tank optional

Heating method:

electricity heating/steam heating(electricity/LPG/diesel oil/nautral gas)

Material:

Interior stainless steel 2.5~3.0mm, exterior stainless steel/luxury red copper 1.5~2.0mm

Insulation layer:

polyurethane or rockwool, thickness 80~100mm

Fermentation:

jacket conical fermenter tanks/unitanks' capacity&quantity customized;

Stainless steel material, compression resistance design, design pressure 0.3Mpa, working pressure 0.15Mpa, 48 hours pressure test for both interior and cooling jacket;

Polyurethane insulation and stainless steel cooling jacket, 60 degree bottom cone;

Single tank, single control

Beer storage tank:

bright beer tank/serving tank, jacketed or non-jacketed, 150 degree bottom cone, with carbonization device assort

Cooling:

double stage cooling, cooling system for both Heat Exchanger and fermenter

Cleaning:

50L/100L CIP cleaning, movable with wheel

Standard Feature:

*Stainless steel material 304/316

*Exterior thickness: 2.0mm

*Interior thickness:3.0mm

*Exterior: stainless steel/luxury red cooper

*Flange&dish head(single/double head)

*Temperature sensor

*Top or side manhole

*Insulation thickness 100mm

*Rotary cleaning ball, 360 degree no dead corner

* Hot water tank available&optional

Equipment Components:

| Equipments Request | Components |

| 1. Milling System | Malt Miller |

| 2. Mashing System | Mash/Lauter Tun |

|

| Boiler Tank |

|

| Boiler |

|

| Heat Ex-changer |

|

| Wort Pump |

|

| Stiring Device (Optional) |

|

| Other accessories are available: 1.Ornamental Pipe; 2.Mashing Pipeline; 3.Operating Plateform; 4.Yeast Feeder; 5.Venturi Tube; 6.Butterfly Valve DN40; 7.Butterfly Valve DN32; 8.Soft Pipe; 9.Dregs Rake; 10.Sugar Measuring Cylinder; 11. Saccharimeter; |

| 3. Fermenting System | Fermentation Tank |

|

| Other accessories are available: 1.L-Pipe; 2.Butterfly Valve; 3.Pressure Gage; 4.Solenoid Valve; 5.Vacuum Valve; 6.Cooling Pipe; 7. Thermal Insulation Pipe; |

| 4. Cooling System | Ice Water Tank |

|

| Refrigeration Machine |

|

| Centrifugal Pump |

|

| Evaporator |

|

| Ice Water Pump |

|

| Relative Pipes and Valves |

| 5. CIP System | Washing Tank |

|

| Sterilization Tank |

|

| Pump and Valve |

| 6. Filter System | Kieselguhr Filter |

|

| Membrane Filter |

|

| Filtered Beer Tanks |

| 7. Packing System | Fresh Keg Packing Machine |

|

| Pop Can Packing Machine |

|

| Glass Bottle Packing Machine |

| 8. Controlling System | Mashing Control Panel |

|

| Fermenting Control Panel |

|

| Refrigerating Control Panel |

The Product Details Display

Brewhouse Unit:

1.Mash tun, Lauter tun, Boiling kettle,Whirlpool tun in various combination.

2.Hot water tank and cold water tank for optional in special combinations.

3.Infusion or decoction brewing methods are designed exactly.

4.Stainless steel cladding is even the unique because of easy maintenance and clean.

5.Two stages or single stage heat exchanger for wort cooling.

6.Completely stainless steel integrated work platform.

7.Sanitary and efficiency wort pump.

8.All pipings, pipes mainford and fittings.

Fermentation Unit:

1. Standard stainless steel conical cylindrical fermentation tanks.

2.Single size as brewhouse is common used in restaurant.

3.Tanks quantity is exactly calculated by fermentation cycle for various beers.

4.All manhole, valves, pressure gauges, fittings etc. are included.

CIP System:

Pre-sale service:

1. The 24hours marketing team service.

If you are interested in any product, please don't hesitate to contact us. We will quote you, and give you all the details you need at first time.

2. We can provide company’s qualification certification and the drawings.

All of our products are passed CE test. We can show you our qualification and certification. And we can provide the drawings to make you use our products well as quickly as possible.

After-sale service:

1. We provide long-term after-sale service.

We don't just provide Mini Brewery Beer Manufacturing Plant For Brewing Mash Tun Brew Kettle, the service after sale is same important for us.

2. Owing to the quotation of our equipment is FOB price which excluded charges of door-to-door service. Thus, if necessary, we can appoint our technician to debug the machine with air ticket, visa, accommodation and labor cost provided by your party. Or you can send your technician to our company to learn techniques.

We consider all different potential situation in the delivery, so we use every prevention measures to avoid any potential inconvenience or trouble

Bulk cargo: Standard wooden case which can avoid any clash during the sea or air transportation in case of causing damage to the surface of our products.

Container cargo: the equipment will be bound firmly and won’t easily swing to the side, or up, or down.

Why Do You Choose Us?

1.Top cone of all tanks are mirror polished.

2.Shadowless manhole

3.Our skilled workers are with more than 10 years welding and related production experiences.

4. Our installation engineers are with more than 10 years brewing experiences, which can train or help you brewing customers-liked beers.

5. High quality milled falsed bottom installation method: special discharging handle, easy to discharge and clean.

6. Led cold light, bright , lower power consumption and lasting, other suppliers only use normal light ball.

7. Imported food grade rubber hose, long lift-span, safe and firm.

8. Large spent grain door, reliable sealing, with hopper, easy to make the spent grain out without ground pollution.

9. Mechanical pressure adjustable valves: plus and minus pressure protection, ensure the tank safety.

ours test.

Component Parts Display

Product Categories : Microbrewery system